Progress today

New(er) front caliper assembly

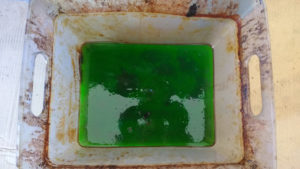

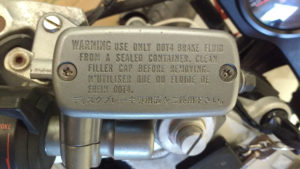

Drained and disassembled new-to-me right front brake caliper. Cleaned/polished interior, piston edges, exterior, hanger pin, etc.

Right caliper mostly apart

Checked existing pads. Found them to be EBC HH in very good condition. They measure same thickness as new pads. Scrubbed braking surfaces and reinstalled the pads in the caliper. Reassembled caliper and installed on the fork leg with polished bolts.

Completed same process for the left front caliper, but found extra part at the end.

Pad spring and otherwise assembled left caliper

Disassembled again, assembled with all parts, and installed on the fork.

Removed rear brake assembly including pedal/peg/master cylinder unit, fluid reservoir, and caliper with hoses. Disassembled new to me rear brake caliper. As for the fronts, found EBC HH pads with little wear.

While the rear was naked, scrubbed and wirebrushed the swingarm, hub, sprocket, brake disc, and brackets. Polished brake mounting bolts. Reassembled rear brake caliper and installed on the bike.