Posted updated checklist (V4)

Progress today

Shopped supplies, tools for forks. No luck yet on plastic pipe/tube for bushing/seal driver. 1-1/2″ PVC coupler is too large and too thick. Fork stanchion tubes are 41 mm diameter (about 1-5/8″).

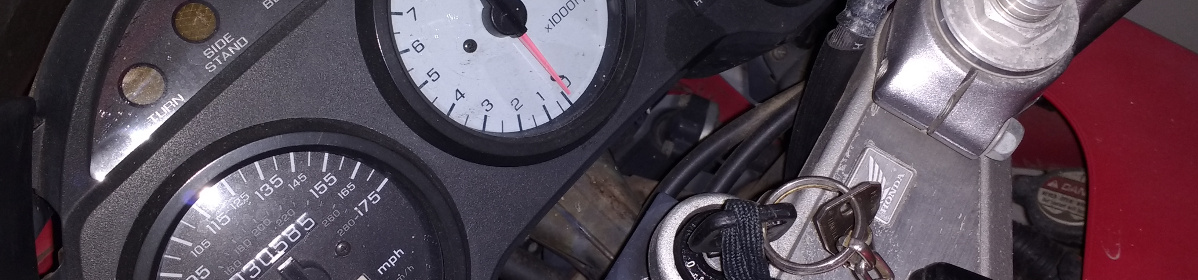

Bought and installed more stainless fasteners. Notably front master front cylinder screws.

(compare to before)

First attempt at ABS plastic welding with cement. Used cleaner (mostly acetone) and medium black cement to fix broken mounting tab of right front turn signal body. Set up in less than a minute. Left to cure for about 4 hours. Assembled into upper right fairing section. Worked like a champ – very solid. Expect good results for body plastic, too.

inside view, lamp out

lamp in

outside