Posted an updated checklist (V5)

Progress today

Removed front wheel. Wirebrushed/cleaned axle, spacers. Washed wheel and disks. Polished disk with scotchbrite, brake cleaner and fine sandpaper to clean all braking surfaces.

front wheel (before)

front wheel (before)

front wheel (after)

front wheel (after)

Fabricated wheel balancing stand from flange and iron pipe on workbench leg. Tested. Looking good.

Made seal and bushing driver out of vet pill bottle. Cut off the bottom and added two hose clamps. Fits perfectly on stanchion tubes. Will see how it works on re-assembly.

Removed clip-ons from forks, then fork legs from the bike.

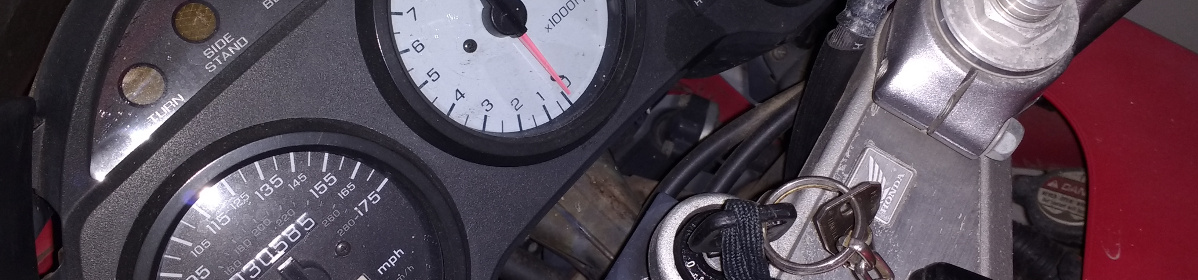

forks fresh off the bike

forks fresh off the bike

Cleaned outside of forks, scrubbed with scotchbrite pad. Removed stickers, degreased and sanded lowers (sliders) in prep for prime and paint.

Pulled bottom bolt from left fork, but couldn’t break the right one loose. Starting to strip the hex head. May need to do bolt extraction.

Disassembled left fork leg: pumped oil out of bottom hole. Pulled out rotten dust seal. Found retaining ring a little corroded. Oil seal significantly deteriorated with solid crud crust. Took considerable slide-hammering to remove it and the bushing. Both bushings in good shape with no scoring or noticeable wear.

left leg parts (before)

left leg parts (before)

Cleaned inside slider tube and pried off fork protector. Did final scuff sanding and degrease on slider, then primed and painted it.

left slider after paint

left slider after paint

Polished both stanchion tubes to flatten rust pits. Used (000/0000) steel wool and WD40. Used fine file with no pressure to clear the larger spots. Not perfect, but they are very smooth to the touch with no raised edges to catch rubber seals or score the bushing.

stanchion tubes after polishing

stanchion tubes after polishing