Progress today

Made extended tailpipe gasket from 0000 steel wool and blended over the existing gasket portion on the factory header pipe. Fitted up new Delkevic muffler and tailpipe with supplied brackets and hardware. Wiggled a bit to get the pipe behind the passenger peg bracket and up under the bodywork edge.

Test fitted the right rear fairing piece to check clearance and alignment with the muffler. Looks really good and the bodywork just clears the muffler mounting bolts and hanger.

Later … removed the right engine cover for repair/repaint. It’s significantly corroded and has a scrape at lower left.

This exposed the clutch and assorted inner bits to view.

Had issues with 3 of the 8mm bolts holding the cover. Eventually used a bolt extractor, 1/4″ deep socket, and breaker bar (thanks to Dan) to get them broken loose. Organized them all on cardboard to be sure they go back in the same holes.

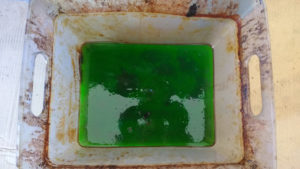

Carefully scraped old gasket material off of the inside of the cover and mopped out old oily spots.

Next:

Clean the mating surface on the engine case. Clean, sand, prep, and paint the outside of the cover, then reinstall.