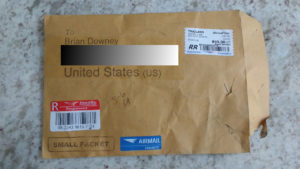

About a month in the air, apparently. Expected it would be this long, but still amazing 🙂 Mail attempted delivery Saturday, fetched from Post Office today.

Front wheel, forks off

Posted an updated checklist (V5)

Progress today

Removed front wheel. Wirebrushed/cleaned axle, spacers. Washed wheel and disks. Polished disk with scotchbrite, brake cleaner and fine sandpaper to clean all braking surfaces.

front wheel (before)

front wheel (after)

Fabricated wheel balancing stand from flange and iron pipe on workbench leg. Tested. Looking good.

Made seal and bushing driver out of vet pill bottle. Cut off the bottom and added two hose clamps. Fits perfectly on stanchion tubes. Will see how it works on re-assembly.

Removed clip-ons from forks, then fork legs from the bike.

forks fresh off the bike

Cleaned outside of forks, scrubbed with scotchbrite pad. Removed stickers, degreased and sanded lowers (sliders) in prep for prime and paint.

Pulled bottom bolt from left fork, but couldn’t break the right one loose. Starting to strip the hex head. May need to do bolt extraction.

Disassembled left fork leg: pumped oil out of bottom hole. Pulled out rotten dust seal. Found retaining ring a little corroded. Oil seal significantly deteriorated with solid crud crust. Took considerable slide-hammering to remove it and the bushing. Both bushings in good shape with no scoring or noticeable wear.

left leg parts (before)

Cleaned inside slider tube and pried off fork protector. Did final scuff sanding and degrease on slider, then primed and painted it.

left slider after paint

Polished both stanchion tubes to flatten rust pits. Used (000/0000) steel wool and WD40. Used fine file with no pressure to clear the larger spots. Not perfect, but they are very smooth to the touch with no raised edges to catch rubber seals or score the bushing.

stanchion tubes after polishing

Front brakes apart

Progress today

Emptied and cleaned out front brake master cylinder.

diaphragm, plate, cover sequence/down sides for master cylinder

Tested brake lever and found smooth action and pumps fluid. Noted tiny part loose in bottom.

Checked against clutch master for position of that piece …

Removed front brake assembly from the bike. Disassembled to leave hose assembly for later sale (?) and recover the right side reflector and bracket. Did basic clean on parts and fittings. Calipers will need teardown and rebuild. OEM Piston seals and boots on order.

Later … wire-wheeled new (old) brake pedal, received today.

Plastic fix: turn signal

Posted updated checklist (V4)

Progress today

Shopped supplies, tools for forks. No luck yet on plastic pipe/tube for bushing/seal driver. 1-1/2″ PVC coupler is too large and too thick. Fork stanchion tubes are 41 mm diameter (about 1-5/8″).

Bought and installed more stainless fasteners. Notably front master front cylinder screws.

(compare to before)

First attempt at ABS plastic welding with cement. Used cleaner (mostly acetone) and medium black cement to fix broken mounting tab of right front turn signal body. Set up in less than a minute. Left to cure for about 4 hours. Assembled into upper right fairing section. Worked like a champ – very solid. Expect good results for body plastic, too.

inside view, lamp out

lamp in

outside

Subframe clean

Progress today

Noticed that fuel pump was hanging loose. Found rubber mounts split. Clamped rubber to pump body and assembly to mounting ears with zip ties. Is very firm, and still rubber-isolated from frame. New rubber mount is OEM part# 16711-MZ7-000 ($16.95 at BikeBandit).

Cleaned up rear sub-frame area. Cleaned parts, wire runs, fender assy, metal bits. Removed dirt, dead bugs, leaves, other dust. Lubed seat latch and helmet lock parts.

Built prop on dolly to support front end of bike off the ground. Installed. Ready to remove front brakes, front wheel and fork legs.

Next

Remove brake calipers. Remove front wheel. Remove, polish fork legs.

More tank cleaning

Progress today

Soaked gas tank – filled with pine cleaner solution overnight. Shook occasionally. Drained (mucky) and rinsed with clear water this morning. Sprayed fast stream inside – many tiny flakes coming out. Air dried.

Ordered POR-15 clean/coat kit to complete treatment of tank.

Next

Fork removal, disassembly, seals, oil

Polish windscreen, begin tank cleaning

Progress today

Scrubbed front fender – ready for prep & paint.

Cleaned windscreen. Polished screen with headlight compound. About 4 passes total front and two on the back, working in small areas: about 2 hrs effort. Pretty good clarity now with a slight gray smoked effect. Sufficient for the moment (compare to before).

Disassembled gas tank. Removed filler cap, fuel level sensor unit, fuel petcock, and fuel hose/filter assemblies.

Cleaned filler opening on tank and filler cap surfaces.

Replaced fuel filter with glass aftermarket unit. Attached 3/8″ adapters with teflon plumber’s tape. Clamped tank end. Hose was clear.

Emptied about 1/2 gallon of nasty black liquid from tank. Found about 2″ of sludge/tar at the lower end where the fuel petcock/screen enters. Level sensor coated with sludge. Pickup tube/screen coated to 2″ from bottom. Petcock almost immoveable and full of tarry sludge. Scraped/brushed and cleaned both assemblies with solvent.

Fuel level sensor assembly (after cleaning)

Petcock assembly after external cleaning, new inline filter

Disassembled screen and petcock.

Petcock and screen cleaning in progress

Removed o-ring and valve handle. Pulled tar out of both screen tubes and petcock body using dental pick. Soaked petcock body in Gunk can (thanks Dan!), about 2 hrs. Final cleanout with QTips. Valve action now crisp and easy.

Used fingers to pull out gunk from tank within reach of petcock hole. Added two hands full of pebbles and half gallon of gas and swirled/shook tank for about 30 minutes. That got another pound or two of tar out. Rinsed/swirled several times with water/pine cleaner, then Xylol (xylene), then gas. Lower end of tank needs further cleaning.

Next

Soak tank innards for 24hrs with pine cleaner solution. Flush tank, seal/coat. Reassemble.

Disassemble front bodywork

Progress today

Disassembled front end bodywork ass’y. Removed and polished headlight ass’y. Separated body panels. Moved fasteners, ducting to new right panel. Cleaned all panels and polished visible mounting bolts. Existing center and left sections will need re-paint.

old, damaged right-front panel (inside)

new right-front panel (inside)

Cleaned and polished airbox ass’y, added new air filter and prefilter media. Ready to reinstall.

airbox, filter, cover

Removed front fender, ready for clean/prep. Faded, scratched, will need paint. Polished decorative mounting bolts.

All bodywork now off bike. All but mid-fairings and two new right-side panels to be painted.

(fuzzy) naked bike

Next

Polish windscreeen. Clean/clear/inspect tank and petcock assembly. Replace fuel filter in existing rubber mount.

Disassemble rear, remove front fairing

Updated checklist posted [V3].

Progress today

Completed removing turn signal from left side rear fairing. Screw frozen, stripped. Used drill and manual screw extractor to remove. Replaced original rusted steel screws with new stainless for both rear turn mounts. All rear plastic now ready for repair (then paint).

Removed front upper fairing assembly. Extracted left flange screw – plastic threaded brass insert spun. Removed and re-habbed mirrors and boots. Reference note: mirror mount points (bolt holes) are 55mm apart. Cleaned out debris. Cleaned/refinished dash, black rubber and plastic parts.

Mirror inner covers (after)

dash area (before, after)

windscreen (needs serious polishing)

End of the day:

side and front

Misc cleanup, disassemble tail

Polished grab handles …

… and blackened rear fender.

Removed chain guard.

chain guard in place, center clamp w/brake hose

Brushed metal clamps. Cleaned and vaselined black plastic.

after first treatment

Disassembled tail section. Cleaned parts and polished up tail light and turn lenses.

Attempted reassembly with new right side plastic. Changed mind – will fix original left side plastic first. Possibly wait for paint.

old right side w/cracks (use for plastic weld practice, then discard)

old left side w/cracks (will repair, reinstall)